Biodegradable Plastics Market and Application of HPC-3510P

According to statistics, China’s production of plastic products in 1990 was only 5.5 million tons, to 2019 the total value of national production of plastic products has reached 81.84 million tons, year-on-year growth of 3.91%, at the same time, a large number of plastic products after the use of waste, due to improper handling of environmental problems, has become a hot spot of global concern.

Biodegradable plastic refers to the provisions of the environmental conditions, after a period of time, material significant change and loss some performance, chemical structure, broken plastic, according to the degradation of way points, biodegradable plastics can be divided into light degradable plastics, biodegradable plastics, degradable plastics, biodegradable plastics, and water points according to the material source, can be divided into biological base of plastics and oil base.

The biodegradable plastics advocated in the market at this stage are fully degradable plastics, which can be completely degraded in the soil to achieve the real sense of green environmental protection. Up to now, there are dozens of biodegradable plastics developed worldwide. It mainly includes PLA, PHA, PBS, PBAT, PCL and other monomers or natural polymer materials for the synthesis of these materials.

Biodegradable plastic products mainly include tableware, film, film paper, express bags, clothing, plastic tape and so on. Biodegradable plastics downstream are mainly used in packaging, agriculture, 3D printing, modern medicine, textile industry, etc. PLA, PBS, PBAT and PHA are the main development directions of biodegradable materials in the future. PLA and PBS had the largest consumption in the fields of packaging, textile and agricultural film. PHA is widely used in medical implant materials in some high value-added fields.

In the use of degradable materials, there are mainly three kinds of problems:

(1) Synthesis and storage problems.

For example, the purity of lactide, the monomer of PLA, is too low to produce l-lactic acid with a purity of 99.5%, resulting in poor mechanical properties of PLA, which cannot meet the mechanical strength and strength retention time required by biological materials, and limiting the application range of PLA. Long-term sto rage and external environment can also cause degradation of PLA and PBAT.

(2) processing problems.

PLA molecules contain hydroxyl and carboxyl groups respectively at both ends. Thermal degradation and hydrolysis during processing lead to a decrease in molecular weight and an increase in the number of carboxyl groups (carboxyl groups promote degradation), so the melt strength of the polymer is not enough to be blown or extruded.

(3) Compatibility problem.

The shortcomings of PLA, such as poor toughness, low crystallization rate and poor thermal stability, limit the further application of PLA. Usually, the method of alloy blending is used to improve the brittleness of PLA, improve its flexibility and impact strength. However, PLA is incompatible with other materials and will encounter compatibility problems in the process of processing.

The role of chain extender can be summarized as follows:

(1) Through the molecular weight, increase the melt strength and viscosity, so as to improve the film blow molding productivity.

(2) Improve the compatibility between different varieties of polyester resin.

(3) Through the stability of the hydrolysis of the product.

(4) Improve the processing stability of regranulation of recycled material.

Bio-master ® HPC-3510P is a functional copolymer with ultra-high epoxy content and a particle-like appearance.

The product is characterized by high reactivity, which can provide excellent chain extension scheme for polylactic acid, PBAT, PBS and other easily degradable polymer polycondensates, increase the viscosity of degradable resin, and improve the processing performance of degradable resin to the greatest extent.

Provide excellent compatibilization solutions for PLA/PBAT, starch filled polylactic acid, improve mechanical properties, thermal properties, processing properties and so on.

In this issue we will introduce the application of HPC-3510P in PLA/PBAT filled with CaCO3

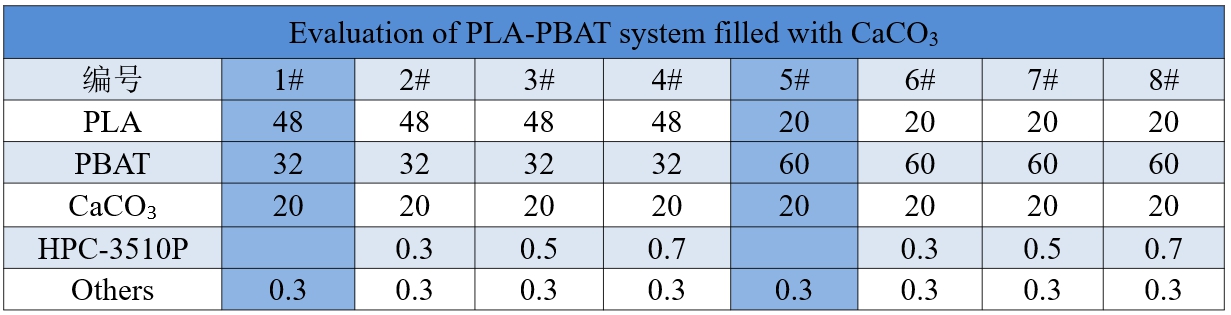

The PLA/PBAT ratios were 48/32 and 20/60, respectively, and the calcium carbonate ratio was 20. A total of eight groups of experimental data were presented to show the application of HPC-3510P in starch filling under different dosage.

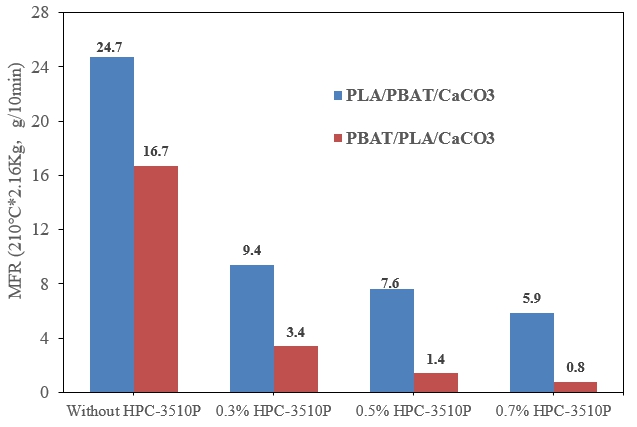

The figure above shows the influence of HPC-3510P addition amount on PBAT/PLA/CaCO3 MFR of different proportions, which gradually decreases with the increase of HPC-3510P addition amount. Calcium carbonate acts as a cross-linking point internally because of the strong reaction activity between calcium carbonate and epoxy functional groups

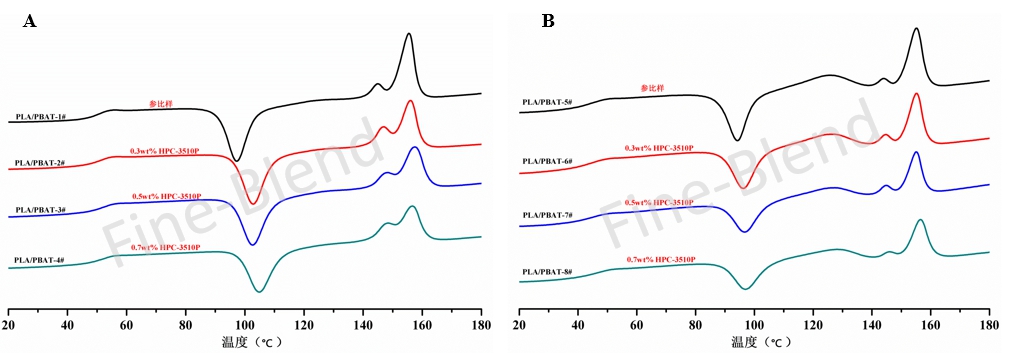

The figure above shows the influence of HPC-3510P addition amount on the melting and crystallization behavior of PBAT/PLA/CaCO3 composites.

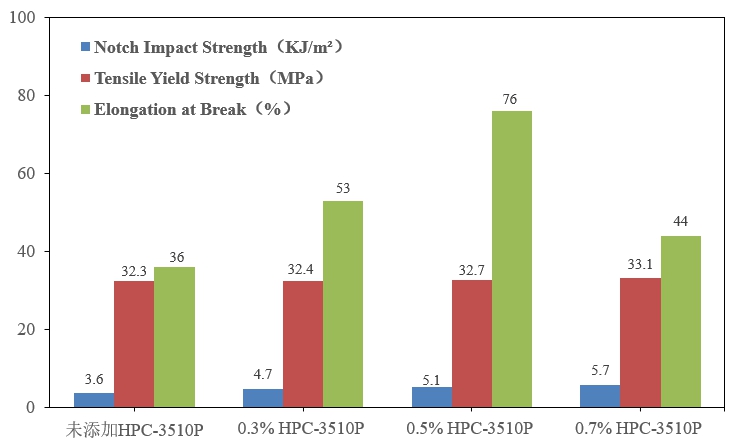

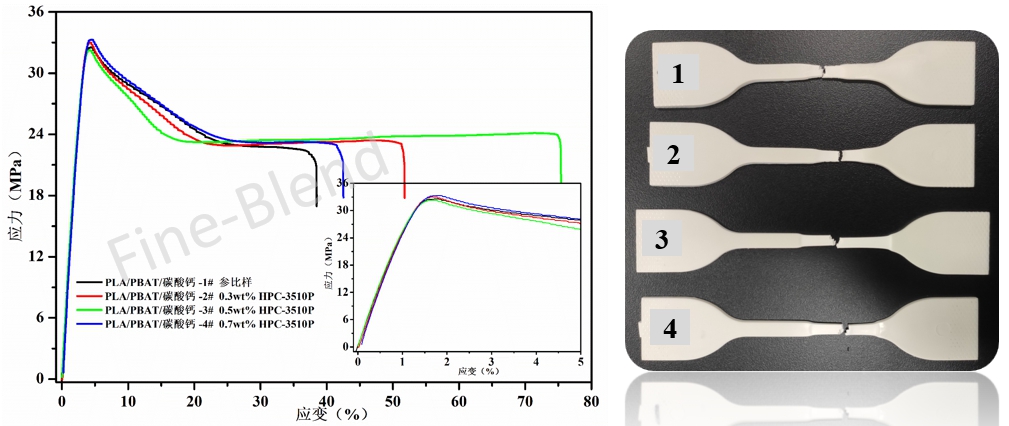

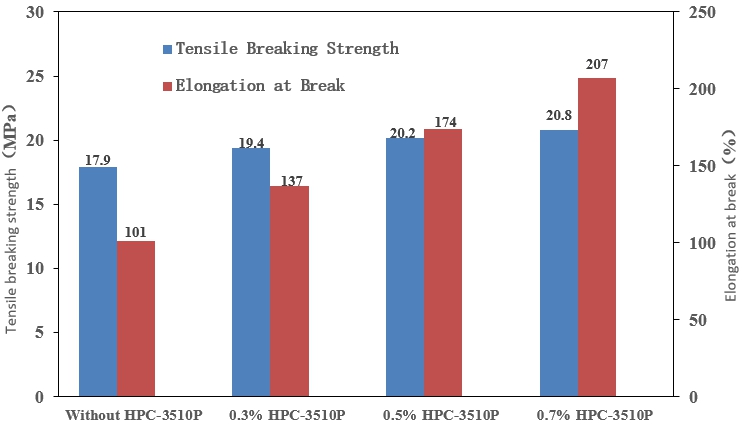

In the figure above, experiment No. 1-4 shows the influence of different addition amount of HPC-3510P on mechanical properties and stress-strain behavior of PBAT/PLA/CaCO3 composites.

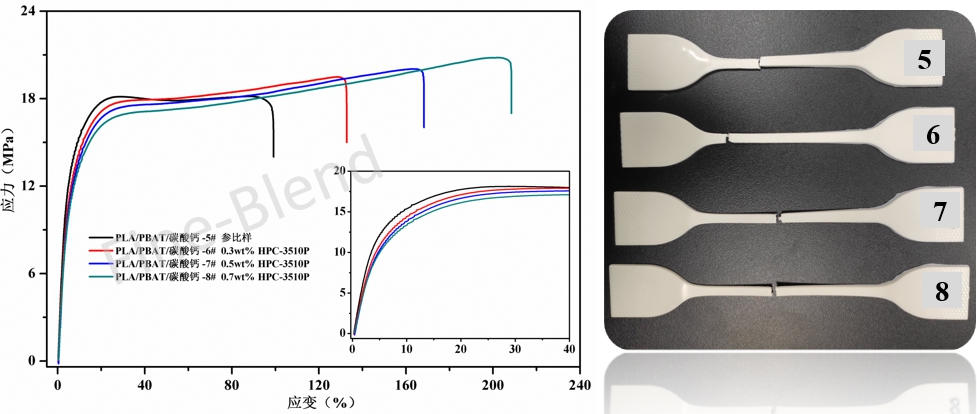

In the figure above, experiment No. 5-8 shows the influence of different addition amount of HPC-3510P on mechanical properties and stress-strain behavior of PBAT/PLA/CaCO3 composites.

In conclusion, the addition of HPC-3510P further improves the processing stability, compatibility and comprehensive properties of PBAT/PLA/CaCO3 composites with different ratios through in situ compatibilization reaction. Meanwhile, in situ compatibilization reaction also reduces the fluidity of the composites, thus reducing the overall melt crystallization performance of the composites.